The legacy continues by our making available the original Marshall- and VOX-style Radiospares (AKA “RS”) transformer designs — some of the most unique and highest quality transformers ever made. Ask any British guitar amp aficionado about Radiospares and they’ll bend your ear for hours about the these incredible-sounding VOX and Marshall amps.

Mercury is extremely proud to offer these outstanding transformer designs. All Radiospares transformers come with both our 10-year Workmanship Warranty and Tonal Guarantee. Radiospares transformers may be used for upgrades, replacements or custom tube-based guitar amp applications.

To find out more, or discuss to discuss the characteristics of the different transformer sets available for your amps, give us a call or email.

A few months back, we restores a 1960 Vox AC15 to it stellar sonic signature. But as with all vintage amps, you never know when something might go on the fritz!

We had just tightened the last screw and powered up the amp to unleash some ear candy when – major bummer – there was a noticeable loss of signal. After a diagnostic check, everything pointed to the output transformer. So it was off to Mercury Magnetics and the meticulous mind of its founder, Sergio Hamernik, to re-wind this 51-year-old piece of harmonic history back to spec.

VG: So… is it all over for this output transformer?

Sergio Hamernik: Well, it appears that it’s given up its ghost. A major bummer to say the least! Replacing a transformer in a guitar amp is a similar feat to heart surgery. But it’s NOT “All Over Now Baby Blue” because we’re going to fix it. And when we do, it’ll likely sound better than the original.

This output transformer is an original, from 1960. The late 1950s into the early 1960s was a transitional period for VOX. And one in which their transformers were known to have various failure rates, depending upon which batch ended up on the chassis.

In your case, someone from the original transformer company had the bright idea of using low-cost wax instead of a varnish dip. No doubt to save their six-pence. To be fair, most transformer companies back then were somewhat ignorant to the unique demand placed on transformers by the guitar amp builders. As a means to inhibit rust on the iron core and also to fortify the insulation of the windings, the industry standard is to dip and bake transformers in varnish, NOT wax. And you know what happens to wax when it heats up!

When we originally opened this amp up, there was wax all over the chassis that had to be scraped out.

There is some merit to using wax if the component doesn’t generate much heat above ambient temperatures. Output transformers do not generate much heat by them themselves. Especially when they’re working within their design specs – even with the amp cranked. But what the original transformer maker failed to take into consideration was all the tubes packed in there next to the transformers on a limited size chassis. As you might have already experienced when you try to pull a tube from a powered up amp – they do get really hot.

Class A amps run hot because they’re designed to run wide open, no matter where you’ve set the knobs. Now enclose this or any amp into a box and you have created an ideal environment for a large temperature rise above room temperature. You can practically see the wax dripping off the transformer.

Plus, VOX amps are notorious for getting hot inside the cabinet anyhow.

Yeah, but VOX wasn’t the only company that stuffed wax transformers into their hot boxes. As we discovered during the course of rebuilding transformers from old Dynaco, Sunn, Marantz, and a few others, they tried this idea and had their share of failures, too. Using wax as an insulator would never fly today because it’s is extremely flammable. Is there such a thing as a nonflammable wax candle? Today’s amps though are probably the safest they’ve ever been.

How long did this wax-period last?

A few years of trial-and-error seems to have put a stop to that practice. The interesting thing is that among the first VOX amps built they used Radiospares transformers. Radiospares were extremely well constructed, varnished and expensive for their day. VOX amps with these transformers are highly sought after (“pre-wax debacle era”). However, I don’t believe VOX ever intended on using Radiospares for anything but prototyping and the earliest short-run productions.

Back then Radiospares catalogs were essentially England/Europe’s equivalent of the American Allied/Radio Shack catalog stores. We’ve run across a few early AC30s that came with their full compliment of Radiospares transformers. If they had failed it was due in part by operator error and not the construction of the transformers themselves.

It seemed that shortly after the Radiospares era VOX began to solicit other transformer companies. An early one that comes to mind was Parmeko. Based upon our forensic investigations, Parmeko seems to have been a low-bidder – which was clear by their rather feeble attempt to copy the Radiospares. Also, the Parmeko output transformers were dumbed-down with cheap materials and short-cut winding methods. Their transformers were in no way even close to the Radiospares quality, as their lack of tonality proved.

The engineering of the original Radiospares designs and workmanship are highly respected by us. They’re extraordinary, and for that time they really raised the bar – as demonstrated by Eric Clapton’s sound on the “Blues Breaker” album – a JTM-45 Marshall using the same Radiospares transformers!

What time period are we talking about?

This was during the first year of production for VOX of these amplifiers.

So… the output transformer in this AC15, is that a Parmeko?

No. It’s definitely after Parmeko, which once again marks another transitional period in the company’s history. Soon after Parmeko, VOX found another transformer supplier, Woden, a former military supplier who bid low to get the VOX order. Your transformer shows all of the tell-tale signs of it being a Woden.

Woden had some problems with quality and consistency. So the performance of their amps varied from transformer batch-to-batch. I wouldn’t be surprised if Woden was behind the idea of changing their production run to wax the transformers. Many amp players and collectors are quite fond of these Woden-era amps.

The Beatles era marked another transition for VOX. From Woden to Haddon, and Haddon is generally what people recognize when they think of that Beatles sound. Haddon was another former military contractor, but a step UP in build quality and consistency and probably cost from the Wodens.

If I were to purchase a vintage AC30, for example, I would look for the ones with Haddon transformers, although I still prefer Radiospares because they consistently give that benchmark tone. When the Beatles and the British rock seen took off in the early ’60s, VOX grew into a big corporate thing. At that point the Haddons were becoming just too expensive – so enters another transition in their transformer suppliers – a lower-cost company called Albion.

Although VOX saved money with Albion, their transformers created an interesting and more aggressive new VOX tone. Sadly, right after the Albion era the company went to Thomas Organ and shifted over to solid-state circuitry. And as we all know those were a part of VOX’s darker years.

The Albions do have a small group of followers that really dig that sound. But when I’m thinking “VOX” I’m really talking about the goose bumps that the Beatles era gave me with the Haddons. George Harrison had no problem overdriving his VOX amps into that unmistakable jangle and sparkle tone. Nor did Brian May with his signature thick and creamy textured sound.

For the record we have cloned Radiospares, Parmeko, Woden, Haddon and Albion transformers from that era and make them available in our catalog.

Did this transformer die because the wax had melted away?

Probably not. This transformer lost its wax at least 40 years ago. But even that’s okay. I have built amps and prototypes in the past where I used unvarnished transformers and they performed just fine. The main purpose varnish or wax is basically to coat the iron core. Rust proofing it because the better the grade of iron the greater the chance for rust to settle in. London fog didn’t help things either. Actually the coil’s insulation itself doesn’t always depend upon the use of varnish. So your transformer probably led its life mostly free of the wax, and it still performed well.

So why did the transformer die?

Transformers are not apt to commit suicide… no matter how poorly one plays the guitar. Transformers in general are not subject to the effects of aging. Instead, they usually die at the hands of others.Consequently, it’s almost always some outside operating condition or an offending part.

There are a few exceptions though. These come from some well-known and liked amplifiers that over the years have fallen victim to self-destructing transformers. Time bombs of a sort stemming from historically problem-laden transformer designs. More often than not inadequate internal insulation systems. An amp that comes to mind is the first generation of Marshall Majors. Their power transformers would frequently fail from voltage breakdowns. These transformers were a bit oddball since they didn’t appear to follow the build methods of the Drake transformers which are found in the 50 and 100 watt amps of the same production era. Jim Kelly amps another oddity, they came with power transformers with screaming high B+ voltages and an output transformer built with no insulation other than the coating on the magnet wire itself! I believe these were made by the now defunct Time Magnetics.Even the transformers from AmpegB15s are frequent visitors/patients to our rewinding / restoration lab. Since these transformers are in cans, and extremely expensive to repair, most clients choose our ToneClone replacements as upgrades in tone and reliability over the stock transformers. It’s only a matter of time, depending on how many hours are clocked on these amps, before we get that phone call. We see firsthand the failures of transformers like these that are designed without enough insulation to survive the demands a guitar player can put on them.

So was it something else in the amp that’s making the transformer work harder or the wrong way?

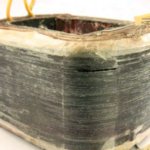

For your particular transformer we’re going to take a series of photographs showing you the rewind/restoration process from beginning to end. In the first photos we’ll show how we received the transformer from you. Take a look at the view of the bottom of the transformer. Notice that there is a tiny, pin-sized burn mark on the outer-wrap of the winding. This bothers me. It looks similar to a bullet entry wound.

Transformers in general can withstand a lot of abuse. But if there is something making the transformer work harder or the wrong way, then something in its operating environment has changed or failed leading to a breakdown. First of all, we noticed fresh re-soldering on the outside of the transformer. The only soldering that should take place are the lead wires to the terminals. There are very fine wires underneath the outer wrap that may get damaged from a lingering soldering irons. We prefer that people keep their dick skinners away from any original solder joints on the transformer.

With regards to your particular transformer we can narrow the problem down into three categories of investigation:

1. The condition of the components that connect to the input of the transformer.

2. The parts and connections that connect to the output of the transformer.

3. The possibility of rough or mishandling of the transformer

Could the transformer have failed from a shorted tube?

Not likely. A shorted tube failure will create a different witness mark on the transformer. A shorted tube usually causes half of the primary winding to light up like the heating elements of a toaster. Scorching a larger section of the input coil. Your transformer does not show any signs of that type of failure. Remember you still had some audio coming out of your amp. You’d be hearing crickets instead if the primary winding was shorted or melted.

On the speaker side?

I have a tendency to believe that it’s a voltage breakdown due either to a lack of load (no speaker connected), broken connection, or some defect or damage done to the winding itself. Another bit of evidence of course is that your amplifier had partial output – it wasn’t completely dead quiet.

Based on how you described the amp sounding it leads me to believe that the failure will be isolated to a small spot on the primary winding as opposed to the coil being completely burned. And I wouldn’t be surprised if the output winding still looks like new. Amps that end their life with noisy output generally don’t suffer from current (short-circuit) related problems.

That’s exactly what I heard when I turned on the amp.

Sometimes if you catch it on time by turning the amp off ASAP you have a chance of saving the transformer. If not, the transformer will eventually fry itself.

So the transformer didn’t see a proper load on it.

It probably was exposed to some form of open or partially open load or a connection. Which will cause out-of-control voltage spikes/arcs to take place beyond what the transformer’s insulation system is designed to withstand. “Transformers Gone Wild” is not a DVD I would recommend. There are no girls in it!

We can restore the transformer to better-than-new condition. But if you don’t find, fix or replace the offending part or bad connection that took it out to begin with before you re-install your resurrected tranny, you may to blow it all over again.

It was originally built around the design of one of Jim Marshall’s favorites, the Fender Bassman; like the Bassman, the JTM45 was actually a fantastic guitar amp. Because of its consistent popularity, Marshall has offered a reissue version of the head — more than 20 years after production of the original JTM45 ceased. While the reissue is built with modern components and assembly techniques, it retains much of the tone, responsiveness and character of the original, hand-wired versions of the early days. No wonder builders today still carry on the tradition of the JTM45, and guitarists continue to seek out the pure simplicity and touch response of this tone machine. To celebrate the JTM45, I got together with my Sunday afternoon amp group, after contacting a handful of respected amp builders who sent us their versions of the amp. We fired them all up alongside an original and a reissue JTM45 to take a listen — and to enjoy one of the best amps ever designed.

About the Authors

About 5 years ago, while playing a 9/11 benefit show, I had the good fortune to meet two people who would not only profoundly impact my life with tube amps, but would become lifelong friends. John Rossi and Tony Burns were there that day; Tony, a killer player and a regular on the Tempe/Phoenix music scene, and Johnny, his friend and amp tech, making sure Tony’s amps were running well in 115 degree heat at the outdoor amphitheater. When I saw Tony’s wall of Marshalls next to my backline of Marshalls, it was an instant conversation starter.

We spent time between sets that day discussing the various finer points of our amps and gawking at each other’s rigs. The show went great but my ’67 Super P.A. felt a bit stiff, and wasn’t reacting in the most flattering way. This incident proved to be the catalyst, as Johnny was an underground semi-retired tech and ultra-fanatic Marshall enthusiast, and he had some ideas that he wanted to try out. He invited me over the following Sunday to check out the amp, and to experiment with various preamp and power amp tubes while BBQ-ing and having a beer. Tony was there, and it became clear that we all had a deep respect for these amps; rather than modify them, we wanted to bring them back to their former glory. After five years, and dozens of hacked-up Marshalls coming back from the dead, here we are. Over that time we’ve learned more about these amazing amps than any of us ever anticipated, and we’ve have had a blast in the process. I have no doubt in my mind, based on my readings of the various amp forums, that there are plenty of groups just like us all over the world doing the same thing.

The Lineup

The lineup consisted of our own 1965 original and 1990 reissue heads, two MetroAmp JTM45s (a kit version as well as the GPM 45), a Germino Classic 45, a Wallace Amplification BKW45 and Mojave Ampworks’ new Special Edition Plexi 45 head. After searching through our collection of cabinets, we settled on both an eighties Marshall JCM800 4×12 with black back 25s, and a Mojave 2×12 cab with 1963-era Celestion Alnico Blues. It may sound strange that there were no pinstripe or basket weave cabs used for the roundup, but that wasn’t for lack of trying. Among all the members of the amp group, we actually have a pinstripe, a basket weave and a variety of Marshall 4x12s, but for some reason we always come back to the early-eighties JCM 800 cab with black back 25s.

That particular cab has more clarity, tone and authority than any other, and it remains our favorite in the bunch — despite the cool factor of the older cabs. The 2×12 with Blues was a natural choice, as that flavor shares similarities with the mid-sixties Marshall cabs and is also a popular speaker configuration for Bluesbreaker combos. The guitars we used were our standard array of Les Pauls from the ’70s, ’80s and 2000s, as well as a newer 2008 Fender Strat and two early-seventies Strats. With everything in the room (it was quite a sight!) we were ready to begin.

Original 1965 JTM45

Original 1965 JTM45To get our ears accustomed to the JTM45 sound, we began by firing up our ’65 head with a Les Paul. Normally, this head has EL34s in it, but we borrowed the Genelex KT66s from the Mojave and biased the amp to accommodate them. It made sense to us to use KT66s, because they were what the amp was designed for. With everything looking good, we flipped it from standby and beheld the beauty of this vintage masterpiece. It’s no wonder players and collectors are paying big bucks for these amps; everything we played through it sounded incredible.

What was amazing was how much of a rock ‘n roll amp this really is. Considering how long it’s been since it was conceived, the amp’s sound remains surprisingly current. The distortion is organic, full-bodied and earthy, and it allowed the personality of the guitar and player to shine through. While it was very easy to play, this is an amp that still requires a level of discipline and control to fully harness its capabilities. It makes sense that players who want to be heard would play on this style of amp, because like it or not, whatever you play through the amp is… well, amplified. It just comes out better.

We played through it for a good long time, switching guitars and speaker cabinets to hear it in as many different configurations as possible. Whether it was a Strat, a Les Paul, a 2×12 or a 4×12, the sound was always remarkable — perhaps the very definition of great tone. Subjective? Yes. Brilliant? Absolutely. Rolling back the volume on the guitars exposed a beautiful clean tone that was harmonically rich and defined, never muddy or dull. Even with the guitar’s volume knob all the way up, the dynamic response of the amp, and the way it musically fed back, was awe-inspiring.

Once we had established a base tone for comparison’s sake, it was time to play and listen to the other amps. Before I break down each individual amp and builder, I must observe that each and every one of the amps had ridiculously good tone, and they all sounded like JTM45s, but each had its own unique voice. Aside from the reissue Marshall, all of the amps are hand-wired. The reissue Marshall was of PCB-construction, and used the standard parts and components that Marshall was building their amps with during that era. I spoke with Mitch Colby from Korg USA (Marshall’s US distributor), who told me that the reissues have not undergone any significant changes since their reintroduction 20 years ago. While they are using the components that Marshall builds with today, they should yield very similar tones to the earlier reissue amps.

Once we had established a base tone for comparison’s sake, it was time to play and listen to the other amps. Before I break down each individual amp and builder, I must observe that each and every one of the amps had ridiculously good tone, and they all sounded like JTM45s, but each had its own unique voice. Aside from the reissue Marshall, all of the amps are hand-wired. The reissue Marshall was of PCB-construction, and used the standard parts and components that Marshall was building their amps with during that era. I spoke with Mitch Colby from Korg USA (Marshall’s US distributor), who told me that the reissues have not undergone any significant changes since their reintroduction 20 years ago. While they are using the components that Marshall builds with today, they should yield very similar tones to the earlier reissue amps.

George Metropoulos is no stranger to the world of Marshall amps or to the online amp building community. Having run MetroAmp for some time now, George offers everything from fully built replicas of many classic Marshalls to ready-to-build kits and hard-to-find replacement parts for vintage Marshalls. A player, George honed his amp-tech skills by adopting a DIY approach, taking care of his own amp repairs on the road. This extended into repair work at home, and then really took off when amps began coming in for restoration rather than simple re-tubing. After his ’73 Super Lead was stolen from a gig, he realized it might be best to leave the valuable amps at home, and so he embarked on a never-ending quest to replicate the tone of the old Marshalls.

George Metropoulos is no stranger to the world of Marshall amps or to the online amp building community. Having run MetroAmp for some time now, George offers everything from fully built replicas of many classic Marshalls to ready-to-build kits and hard-to-find replacement parts for vintage Marshalls. A player, George honed his amp-tech skills by adopting a DIY approach, taking care of his own amp repairs on the road. This extended into repair work at home, and then really took off when amps began coming in for restoration rather than simple re-tubing. After his ’73 Super Lead was stolen from a gig, he realized it might be best to leave the valuable amps at home, and so he embarked on a never-ending quest to replicate the tone of the old Marshalls.

Like all the builders in the roundup, George is passionate about vintage Marshalls and obsessive over the details that make these amps so coveted. We received two amps from Metro: the JTM45 kit (which can be purchased already assembled for an additional $400) and the GPM45, George’s custom-built JTM45 using NOS vintage parts. When we fired up the MetroAmp 45s, it was clear that they both came from the same camp. Both amps were meticulously built and incredibly precise in their layouts. The main physical differences between the amps came down to the caps, resistors and tubes. Both amps shared the same iron and layout, so they also shared a lot of the inherent tone in their circuits. As George is a fan of the mid-sixties JTM45s, Metro’s transformers are based on the Drakes, rather than the earlier Radiospares iron [editor’s note: Kit also comes with optional Mercury Magnetics transformers]. Still, there was no question that the GPM45, which included NOS Phillips mustard caps, Allen Bradley carbon comp resistors and a gorgeous set of Genelex KT66s, was sweeter sounding.

While those differences accounted for a tonal upgrade, what made the differences even more compelling was the way they affected the touch factor of the amp. Much like our ‘65, the custom-built Metro had an ease about it that felt like a broken-in vintage head, making it a breeze to dig in, or to lay back on the strings and feel the amp act as an instrument. It was truly inspiring. Of all the amps in the roundup, this amp sounded most like our ’65 — frighteningly close! I should mention that the Metro kit version was actually plugged in first, and before comparing it to the GPM45, we all agreed we’d be thrilled to have one in our collection. We may be splitting hairs here to some degree, but knowing that anyone can buy a complete kit for under a grand, and have that kind of quality and tone — that says a lot.

Metro’s JTM 45 Kit:

Metro’s GTM 45 Custom Build:

Wallace Amplification BKW45

Wallace Amplification BKW45Brian Wallace has electronics in his DNA. His father, an electronics engineer, and his grandfather, an RCA tube repairman, were both instrumental in his early education and development in tubes and electronics. When he was young his father gave him a 75-in-1 electronic projects kit and further encouraged Brian by letting him watch as he built his own projects. Like all of the builders in the roundup, Brian is a player. He began modifying amps in 1974, when he removed the speakers and baffle in his Checkmate amp and replaced them with a baffle he created and some purchased speakers — altering the sound of the amp and thus beginning his lifelong journey. In 1995, he was approached by Guytron Amplification to help out while they were getting started. A positive experience, it propelled him to the next level and led to the creation of Wallace Amplification, which now offers several amp models as well as replacement transformers under the Marstran name.

Wallace’s first amp is the BKW45, but he is more than a clone maker. Recently he introduced the Abaddon, which is a 50-watt master volume head consisting of four gain stages in the preamp. There is much more to come, including a line of pedals and a reissue of the Fuzz Ace pedal he made back in the early ’90s. The BKW45 is a unique flavor of JTM45. A hair darker in tone and possessing slightly less gain than all of the other models, including both the vintage and reissue Marshall, it yielded enormous bloom and a bold, thick, sustaining quality. Even though there was a little less gain, it didn’t affect playability, and we never struggled with the amp. It was one of the rarest qualities I’ve experienced in an amp, and certainly an unexpected bonus.

The Wallace had a magical ability to push notes through loud and clear while still being able to dish out gritty and harmonically pleasing chords that didn’t fight the non-perfect intervals they were built on. This all came out of an amp that was using tubes you can buy today without breaking the bank.

The Wallace had a magical ability to push notes through loud and clear while still being able to dish out gritty and harmonically pleasing chords that didn’t fight the non-perfect intervals they were built on. This all came out of an amp that was using tubes you can buy today without breaking the bank.

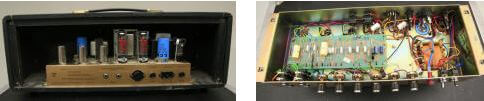

Speaking of breaking, check out the sidebar on what the BKW45 was subjected to by UPS en route to our roundup. In spite of the gorilla treatment it received, the amp arrived without shattered glass and performed flawlessly throughout the entire set of three sessions of playing and listening. That’s a testament to a solidly built and roadworthy piece of equipment. And one look inside the amp will show what a dedicated and precise builder Wallace is. In tone and build quality, the amp is a work of art.

Ever wonder what could happen to your amp in shipping? In the case of Brian Wallace’s BKW45 amp, UPS had a field day, and decided it would be a lot of fun to throw it around. When the amp arrived, it was packed neatly in a new cardboard box with padding inside suspending the padded road case that housed the amp. That’s double-boxed and protected by a case built for heavy abuse. Sadly, it took one good slide down the end of a ramp and collided with either another box or the wall of the truck. Though the box didn’t show any signs of abuse on the outside, it was clear that something had shifted when I opened the case. Take a look at this picture of the damage and the way the entire amp was shifted to one side because of the impact. Believe it or not, the tubes didn’t shatter and the amp worked fine, but it was cosmetically damaged by a broken front Plexi panel. This isn’t the first time this has happened, but it’s the first time I’ve seen it happen with this type of road-worthy packing. Let this serve as a reminder to always insure your amps, as the shipping company can’t tell if you’ve got a bag of peanuts in a box or an amp that was lovingly built by somebody like Brian.

Ever wonder what could happen to your amp in shipping? In the case of Brian Wallace’s BKW45 amp, UPS had a field day, and decided it would be a lot of fun to throw it around. When the amp arrived, it was packed neatly in a new cardboard box with padding inside suspending the padded road case that housed the amp. That’s double-boxed and protected by a case built for heavy abuse. Sadly, it took one good slide down the end of a ramp and collided with either another box or the wall of the truck. Though the box didn’t show any signs of abuse on the outside, it was clear that something had shifted when I opened the case. Take a look at this picture of the damage and the way the entire amp was shifted to one side because of the impact. Believe it or not, the tubes didn’t shatter and the amp worked fine, but it was cosmetically damaged by a broken front Plexi panel. This isn’t the first time this has happened, but it’s the first time I’ve seen it happen with this type of road-worthy packing. Let this serve as a reminder to always insure your amps, as the shipping company can’t tell if you’ve got a bag of peanuts in a box or an amp that was lovingly built by somebody like Brian.

Germino Amplification Classic 45

Germino Amplification Classic 45Greg Germino is another lifelong guitarist who was bitten by the tube-amp bug after catching the Allman Brothers Band back in 1972. He was so inspired by that show that he switched over from acoustic to electric guitar and began taking electronics classes in high school. In 1979, he requested schematics from both Ampeg and Unicord (Marshall’s US distributor at the time) and began his hands-on education with tube amps. He spent the ’80s at an electronics job, and by the early ’90s he was moonlighting doing tube amp repair for a few music stores. He continued to play live with both 50W and 100W Marshalls during that time and moved to Durham, NC to work at Bull City Sound — working on tube amps from the big-name amp companies.

This led to Greg’s being commissioned by Mojo Musical, where he built their Tone Machine amplifier. The following year, 2002, he began work on the prototype of his Lead 55 amp, which debuted in May of 2002. The Classic 45 model is based on the earlier Radiospares-style output transformer, rather than the Drake 1202-103used in the ’65-’66 era, and the circuit is exactly what you would find in an earlier original. The Radiospares-style OT is supplied by none other than Chris Merren, who is highly regarded in the world of Marshalls, and known to make some of the most accurate transformer replicas out there.

The Classic 45 was the only amp in the roundup that used 6L6 power tubes. Greg’s decision to use them was a combination of staying true to the earliest tubes Marshall used on the original JTM45 amps and his belief that the current crop of 6L6s sound and perform better than newer KT66s. NOS and vintage 6L6s are also less expensive and more plentiful than NOS KT66s. Our immediate response to the Classic 45 was that it was a lively and aggressive amp, with tons of power that made the pick explode off the strings. In ways it reminded us of our favorite ’67 Super Bass in its volume and attack, but it still retained the sound of a 45. It may very well have been the loudest amp of the bunch, and that volume translated to a feeling of excitement that made the amp extremely fun to play. It was present without being shrill and had a super-tight bottom end, no matter what guitar we played through it. While the Classic 45 had tons of natural gain on tap, it also cleaned up nicely when rolling back the volume on the guitar, revealing a bright and sparkly chime. This amp is a real beast, and it could hold its own against 100W amps without flinching.

The Classic 45 was the only amp in the roundup that used 6L6 power tubes. Greg’s decision to use them was a combination of staying true to the earliest tubes Marshall used on the original JTM45 amps and his belief that the current crop of 6L6s sound and perform better than newer KT66s. NOS and vintage 6L6s are also less expensive and more plentiful than NOS KT66s. Our immediate response to the Classic 45 was that it was a lively and aggressive amp, with tons of power that made the pick explode off the strings. In ways it reminded us of our favorite ’67 Super Bass in its volume and attack, but it still retained the sound of a 45. It may very well have been the loudest amp of the bunch, and that volume translated to a feeling of excitement that made the amp extremely fun to play. It was present without being shrill and had a super-tight bottom end, no matter what guitar we played through it. While the Classic 45 had tons of natural gain on tap, it also cleaned up nicely when rolling back the volume on the guitar, revealing a bright and sparkly chime. This amp is a real beast, and it could hold its own against 100W amps without flinching.

Mojave Ampworks Special Edition Plexi 45

Mojave Ampworks Special Edition Plexi 45Anyone familiar with the JTM45 would surely be jealous of Victor Mason. Not only has he seen more than his fair share of vintage Marshall, Vox, Hiwatt and other rare treasures come through his shop, but Victor recently acquired 26 of the all-time greatest JTM45s ever assembled via the Kronemyer collection, and he’s got the pictures to prove it! This is just one of the factors contributing to the obsessive nature of Mojave (and the associated Plexi Palace). Having been around for over a decade on the internet, Vic has been repairing, restoring, buying and selling vintage Marshalls for quite some time now. Stemming from his early desire to find out how EVH created the classic brown sound, Victor embarked on his journey through countless hours of digging into vintage amps and learning where their strengths and weaknesses lay. Mojave now offers an entire line of amps to serve the classic Marshall tones and well beyond with innovative features and designs. The Mojave Plexi 45 also has two very unique features over a stock JTM45. First is a simple feature to allow volume control by way of throttling the power level. Second is a line level output, which is adjustable and incorporates a ground lift.

Standing apart cosmetically from the rest of the amps, the Special Edition Plexi 45 is built on the same footprint as the Coyote and Scorpion designs, with a white-and-black color scheme and chrome hardware. The head is built with an open grille cage that allows for maximum airflow to keep the set of completely NOS glass cool. The 45 supplied for the roundup consisted of a pair of 1970 NOS Genelex KT66s, 3 Mullard 12AX7s and a Mullard GZ34. Like the Germino, the Plexi 45 is based on the Radiospares transformers, which are custom wound by Mercury Magnetics.

The chassis is a thing of beauty; the .09″ thick aluminum, with a high tensile strength and welded edges and seams will ensure it will not flex, bend or develop fatigue, like the early, folded, softer chassis, and will prevent the heavy transformers from causing the chassis to sink in and sag. Mojave deviates from the original JTM45 by using modern, tight-tolerance parts. Custom manufactured caps and metal film resistors allow each amp to sound as close to the one built before it as the one after it. Consistency is something that Vic definitely strives for, and it shows in the build quality and attention to detail, and the desire to add convenient functionality to his amps.

The chassis is a thing of beauty; the .09″ thick aluminum, with a high tensile strength and welded edges and seams will ensure it will not flex, bend or develop fatigue, like the early, folded, softer chassis, and will prevent the heavy transformers from causing the chassis to sink in and sag. Mojave deviates from the original JTM45 by using modern, tight-tolerance parts. Custom manufactured caps and metal film resistors allow each amp to sound as close to the one built before it as the one after it. Consistency is something that Vic definitely strives for, and it shows in the build quality and attention to detail, and the desire to add convenient functionality to his amps.

We found in testing that not only did the amp have an extremely low noise floor, but that it was an authoritative and powerfully voiced amp. There was definitely something different in the tone of the Plexi 45; it was cleaner sounding, but still very bold. Having been to Vic’s shop, I was fortunate enough to play one of the 26 JTM45s he had acquired, and I’m positive that the experience with those amps had more than a little to do with the design of the custom Mercury Magnetics’ Radiospares transformers made for his Special Edition model. The amp is built like a tank.

Marshall Reissue JTM45

Marshall Reissue JTM45While the reissue looked very similar to the ‘65 on the outside, especially due to the fact that it’s already 20 years old, the differences on the inside were quite pronounced. Assembled with more modern methods, and using a PCB rather than hand-wired turrets, you could easily be fooled into thinking that it wouldn’t perform like the others. This particular amp was the only one in the bunch to use EL34s rather than KT66s or 6L6s, so the sound was definitely different. It was incredibly loud and focused sounding, and actually had many of the characteristics of a Super Lead. The sustain and power of the amp was incredible, and for an amp that can be found used for around $1000, this is a sleeper bargain. Marshall has taken some flak for their amps sounding stiff and cold from the factory, but with a little attention — slightly hotter bias and good tubes — this amp is a monster. And just because it says it’s a 45-watt amp, don’t harbor any illusions that it would be a good bedroom amp. This is a loud and powerful beast, and a tone machine as well.

The Blindfold Test

As a final, fun test, we did a blind study, to see how accurately I could identify each of the various amps in the roundup. Johnny and Tony set up the group of amps, and I sat in a chair with my back turned away from them. With the guitar plugged in, they began to fire up the various amps, and we got rolling. Out of all the amps, I was always able to distinguish the Wallace BKW45, due to it’s slightly darker sound. The Metros were also fairly easy to spot, but I ended up guessing the kit as the custom build and vice-versa. The ‘65 was also an easy amp to recognize, but as ear-fatigue set in, the lines began to blur substantially. Pretty soon, I was confusing the Germino for the reissue JTM, the Mojave Plexi for the Wallace, and the Metros for the real JTM. It just goes to show you that all of the amps performed remarkably well, and you can be fooled when you’re not seeing what you’re playing, so never discount a PCB reissue head as a second fiddle to the real thing. In the mix of a band, these differences become small, and any one of these amps would hold their own any day of the week.

Wrapup

To have the opportunity to play through so many variations on a classic theme was not only fun, it was educational. Each one of the builders excels in creating their own unique version of the great rock and roll amp that Ken Bran, Dudley Craven and Jim Marshall built back in 1962. While like all Marshalls, the JTM45 went through changes in tubes, components and designs over its lifetime, there is a trademark flavor and color that still can be found in all of them. Not everyone can afford a vintage 45, but with the help of these builders we have the opportunity to get into that sound and have build quality that will last for years.

Source: https://mercurymagnetics.com/pages/news/PremierGuitar/PremierG-20.htm

Some interesting discoveries were made during the course of our research, development and playing a whole bunch of the original Marshall JTM-45 amps to help us achieve our benchmark ToneClone transformer series for this mighty amp.

Many thanks also to our player and collector friends for loaning us their amps and offering their insight for the cause. Many hours of tasty licks included. Incidentally, we do actually own one of the first coffin logo offset chassis amplifiers built by Mr. Marshall and crew.

There are more JTM-45 amps built using EL34 tubes than with the legendary KT66 tubes and there is nothing wrong with that. But a change of tube type also requires swapping out the output transformer to get the correct operating impedance and tone.

All of the original (limited run) handmade amps had 6L6, 5881 or KT66 tubes connected to a Radiospares “De Luxe” output transformers. The “De Luxe” model being the premium offering followed down by the “Heavy Duty” and “Hygrade” models. Primary impedance was selected at 6.6K.

The Bluesbreaker’s legendary tone was made by using KT66 tubes and Radiospares (RS) premium transformers. The transformers did most of the work here with their unique high primary inductance and low leakage inductance combined with padded (surplus) primary impedance as compared to Fenders of the time.

Note: With the exception of the transformers the JTM was a copy of the Bassman. An interesting discovery came to our attention here. It seems that most of the amps made during that era had the output leads connected in reverse phase (backwards). Was it by intent or a happy accident? We and a number of pro players seemed to prefer the reverse phase connection after many A/B tests. We had the impression that the speaker cabs sounded better, more articulate.

When the JTM-45 went into full production, the KT66 tubes were switched for EL34s and the Radiospares transformers were replaced with Drake transformers (judging by build quality and style). All to save BIG on costs since at the time Marshall was being hammered by a distribution deal that shot up retail prices for his amps right through the roof (a deal Jim Marshall later regretted). The EL34s were decent sounding tubes, but the new transformers (not so Bluesbreaker-ish) bore no resemblance to the original RS designs. These simplified transformers had a primary impedance of 3.4K with a much more simple (lower labor cost) design.

The bonus here, though, was in the easier to hook-up speaker connections for the player on the road, which also made it more difficult to connect speakers to the amp in reverse.

Another interesting piece of historical data is that when the EL-34 started earning the reputation as an affordable, reliable and great-sounding tube, the people at Radiospares added it to their compatible list of tubes for the RS “De-Luxe” output without changing the 6.6K impedance. And the EL34 still sounds great through the RS output transformer!!

Source: https://mercurymagnetics.com/pages/_misc/FAQ.htm#EARLY_MARSHALLS

Radiospares — leads — 8k primary — standard RS secondary

It doesn’t take too much digging to find a laundry list of boutique amp builders using Mercury Magnetics transformers in their products. From Mojave Ampworks to Joe Morgan Amps to kits from MetroAmp, builders have found that Mercury knows their iron. While transformers rarely receive the same level of attention of NOS tubes, speakers, or even guitar cables, they are a major contributor to tone. Think about it—the power and output transformers are the start and end of the line with any amp.

Based in Chatsworth, California, Mercury Magnetics has been building transformers for close to 60 years. I recently had a chance to talk with Mercury’s Sergio Hamernik to dig deeper into their roots, find out what one can expect from upgrading their iron, and what sets Mercury apart. Prior to our conversation, I had the opportunity to witness the remarkable transformation of an Epiphone Valve Junior modified from stock to hot-rodded, using one of their transformer upgrade kits. Not only was it a noticeable upgrade, it was a revelation in just how important the role of quality iron in an amp is. But because it is the single most expensive part of any amp, it’s no wonder we see so many modern amp manufacturers skimp on the iron to keep costs down. Let’s see what the passionate, and often hilarious, Sergio has to say about his part of the business.

I’ve been seeing Mercury transformers in amps for at least a decade. When did you get into the amp scene?

This happens to be one of our most often asked questions. Even though Mercury Magnetics’ roots go all the way back to the early 1950s, there are guitar players who are only now discovering us. But if an industry insider like you has been aware of us for at least a decade, then I suppose it means I don’t need to lay off any of our sales and marketing staff.

I would attribute most of our lingering anonymity to the old days. Back then, most of our clients from the audio community preferred to keep us as a trade secret from their competitors and the press. The typical transformer-savvy amp builder also didn’t usually want to share the credit with us, or reveal what their “unique” technical advantage was regarding audio and tone. Consequently, we were asked to maintain a low profile and generic look for our transformers for quite some time. On occasion, a customer in the know will spot a small “MM” mark on a transformer from an older piece of gear, and ask if it’s a Mercury. Odds are that it is.

It was the guitar amp crowd that pushed us to go above ground. Now Mercury gives any electric guitar player or amp restorer a taste of what the pros were using, talking about in their studios, and amongst themselves. Many players have told us their amps increased in value when upgraded with Mercury transformers, and this became evident when insurance appraisers began to contact us for verification. However, it wasn’t until the mid-1980s when we began to market our services and various brands to guitar players.

For me personally, I got into the amp scene around the mid- to late 1970s. I just found it to be a nice way to relax from the strain of oversleeping.

Your website shows a large number of amp manufacturers you have replacement/upgraded transformers for. What are your best sellers and why?

There are so many different camps loyal to their particular amp brand, so it would be difficult to single out the best sellers. The best sellers are transitory and change from week to week because guitar amp players are a fickle bunch. That’s why we’ve built the world’s largest catalog of guitar amp transformers where nobody is left out.

But trends tend to follow their own dynamics. And the current worldwide trend seems toward smaller wattage amps—regardless of brand. Conversely, the 100-watt heads are not selling like they used to. Players are gigging with no more than 15 watts and a few pedals. Regardless of playing style, they’re doing just fine abiding by sound level restrictions and kicking ass with the tone we feel Mercury upgraded amps deliver.

These players really get the fact that an amp lacking in tone can’t be fixed with higher power or covered up with a gain mod. An amp that coughs out an asthmatic tone at 50 or 100 watts easily fatigues both music listeners and guitarists. But the audience will stay until the bar closes if the band plays well and sounds great—even with as little as a few watts going through the available PA system.

What can a guitarist expect to hear when upgrading their transformers in a newer amp?

An amp’s transformers are the most important component in determining the quality of amplified guitar tone. And it’s no coincidence that they’re the most expensive parts in an amplifier. Many of the newer amps just don’t have the same “overkill” factor with their transformers as the amps in the ’50s and ’60s. Why? Ignorance and a bean-counter mentality. What’s good for accounting isn’t necessarily good for tone from an amp. Sadly, the people making these decisions are probably not players themselves and don’t seem to realize the damage they’re doing to the industry.

It’s not unusual to find a current production amp with a power transformer running hotter than hell, even without cranking the amp all the way. Or having an undersized, cheaply built output transformer whose sphincter begins to tighten the moment the guitarist reaches for the amp’s volume knob. An amp built around anemic transformers yields only to dull, thin, noisy, fuzzy mids and mushy bass. That’s what makes your notes sound more like farts through a pillow. This overkill factor is probably the only edge that some of the vintage amps have over the newer amps.

We have made it our mission to duplicate the performance of the best original transformer designs of all time. In terms of amplified guitar tone history, these transformers represent the best ever produced. – Sergio Hamernik

Have you ever noticed how most newer amps often weigh less, sometimes a lot less, than the older ones? That’s usually the weight difference between the old and new transformer designs. There is a direct relationship between weight and having transformers that seem to stay cooler and “loaf around” with power to spare, until a player demands more from their amp. It’s like they are waiting around having a card game, waiting for the player to do something. The best vintage tone was born that way. Newer amp tone can be easily improved—if the builder follows some of the same ideas.

Upgrading with quality transformers gives a second chance to a new amp owner to make things right with their tone, by reclaiming that overkill factor. Assuming there are no issues with the amp’s circuitry like bad parts or worn out tubes, a guitarist should hear and feel improvements with the very first pluck of the guitar. They should expect to hear the notes more detailed with overtones, and a quicker and more immediate response to their playing. Clean notes will have less sonic collisions with noise and reveal more bell tones, chimes, etc.

When more distortion is required, the player will sense better control of crunch and when break-up begins to happen. The coughing and hacking that happens when a stock amp is pushed, will vanish with a transformer upgrade. It will be replaced with longer sustains and notes that reach farther. The amp will also sound closer and bigger than the power it puts out—and the bass notes will have a tighter, rounder bottom end. And when pushed, she will still be able to hold that quarter from dropping—no matter how tall her high heels—something most musicians are looking for.

It’s not uncommon for guitarists to report that it took a few weeks of playing to fully realize what they’ve gained in terms of harmonic richness. These players have typically played longer and felt more inspirational emotions sucking them in, as they have invested more time into relearning and becoming reacquainted with their amps.

Many players become very attached to the transformers in their vintage amps. When you create ToneClones or Radiospares and Partridge versions of these classic transformers, how close are they get to the originals?

Radiospares and Partridge are our brand specific clones, whereas ToneClones are “best-of-breed” duplicates culled from the hundreds of other brands that have made transformers over the years.

We have made it our mission to duplicate the performance of the best original transformer designs of all time. In terms of amplified guitar tone history, these transformers represent the best ever produced. In the grand scheme of tone pursuit, these designs are incredibility important and deserve to be considered treasures.

This is an ongoing project for us, spanning almost three decades now. And it couldn’t have been accomplished without the enormous amount of assistance we’ve received from top players and amp collectors around the world.

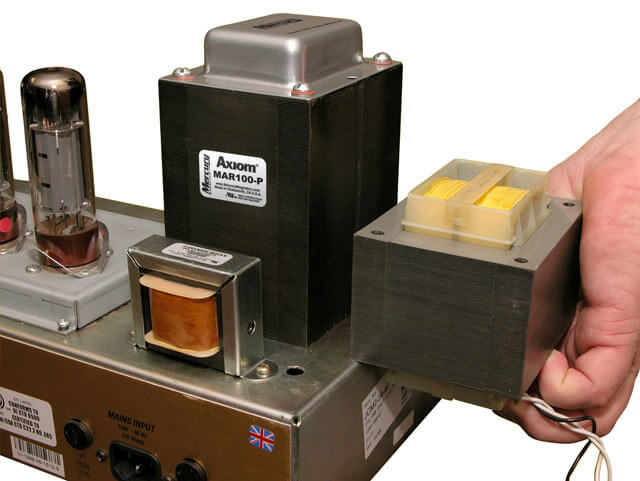

What about Axiom transformers? Where do they fit in?

The Axiom transformer line takes over where the limitations of vintage transformer design ended. No bean counters here—simply the sincere pursuit of answering the age-old question: What if there were no constraints on budget, time, or material quality to achieve the best possible performance? That’s our objective with the Axiom line.

Axiom transformer designs represent many new approaches—new tone with the best materials and designs money can buy, so they’re not intended for the timid or the low-budget crowd. Check out our FatStacks and SuperStacks for the Marshall DSL and TSL families for interesting comparisons.

Mercury’s vintage transformer restoration service has been gaining a reputation for quality work. Why would someone want to restore a transformer instead of replacing it? And vise-versa?

Some vintage amp owners prefer to pay the extra cost of our restoration services, because it’s very important to them that their amps retain authenticity. Collectables or rarities are valuable. They’re of the “why take chances” mind. The high road. But on the flip side, we have pro musicians who insist on touring with their vintage gear. To play it safe, and not sacrifice the tone of their original transformers, they have their techs replace the stock transformers with Mercurys. By doing this, they preserve the original transformers from road abuse while taking advantage of our reputation for tone, durability, and warranty. Restoration of vintage transformers is a tricky and highly specialized art. Sadly, too many of the great originals have been lost forever due to technically inept and musically disinterested people. We see attempts at “rewinds” here all the time.

Occasionally, it appears some people confuse “demolition” with “restoration,” and the preservation of the original tone is lost forever. There’s no shortcut to doing a proper restoration.

I understand you’re doing all of your labor and get all of your materials in the USA. How does that impact your business aside from just the straight costs?

Well, we figured that someone has to do it—and we really do make everything here with 100 percent American materials. There are plenty of products out there stamped with “Made in the USA,” but are actually assembled with non-USA, low-price materials. But yeah, we’re the real deal and proud of it.

Building transformers that make an amp sound good requires highly specialized technologies, highly skilled labor, and the right kind of materials. We love music and owe it to the players out there to do all the work “in-house,” so we can keep tight control over every aspect of our transformer designs. It’s really old-school military spec style, so our transformers don’t vary at all from batch to batch. If you need a replacement transformer 10 years from now, it’ll sound exactly the same as the one it’s replacing.

We’re hard-liners when it comes to not playing shell games with a musician’s hard earned dough and quest for better tone. Perhaps I’m a fool for doing it this way, but I was brought up in a musically minded family. From a very early age, I was taught that music is as important and necessary as food. If there is a day our services are no longer needed or appreciated, I’ll pursue my dream of owning a car wash in the valley, and get into the business of making money.

Any new or exciting projects in the works at Mercury?

Yes, but we’re planning on releasing the news sometime around summer. For quite some time, we’ve been fielding requests for accessories to accompany our transformer line. We’re being asked to apply our know-how to other aspects of guitar amps.

Do you have any advice for guitar players and techs in their quest for tone?

Don’t let anybody fool you—every player has the ability to discern the difference between good or bad tone. Unfortunately, there are a few too many self-styled “experts” who irresponsibly dispense advice without having a clue. As a result, we’ve all seen amps completely lose their tone by being modded to death.

There’s no excuse for the old “damn, I’ve done it this way for many years so it must be right” mentality. More than ever, it’s so easy to seek opinion, advice, and help online and elsewhere. I highly recommend the old textbooks from the 1950s and 1960s as a good place to start on vacuum tube audio circuits.

Do your homework and follow what the smart players are doing—improving your tone isn’t that elusive. If what you have sounds good to you, leave it alone. But if you know your amp’s tone could use some improvement, then start where it begins … the transformers.

Source: https://www.premierguitar.com/articles/Builder_Profile_Mercury_Magnetics

It doesn’t take too much digging to find a laundry list of boutique amp builders using Mercury Magnetics transformers in their products. From Mojave Ampworks to Joe Morgan Amps to kits from MetroAmp, builders have found that Mercury knows their iron. While transformers rarely receive the same level of attention of NOS tubes, speakers, or even guitar cables, they are a major contributor to tone. Think about it—the power and output transformers are the start and end of the line with any amp.

Based in Chatsworth, California, Mercury Magnetics has been building transformers for close to 60 years. I recently had a chance to talk with Mercury’s Sergio Hamernik to dig deeper into their roots, find out what one can expect from upgrading their iron, and what sets Mercury apart. Prior to our conversation, I had the opportunity to witness the remarkable transformation of an Epiphone Valve Junior modified from stock to hot-rodded, using one of their transformer upgrade kits. Not only was it a noticeable upgrade, it was a revelation in just how important the role of quality iron in an amp is. But because it is the single most expensive part of any amp, it’s no wonder we see so many modern amp manufacturers skimp on the iron to keep costs down. Let’s see what the passionate, and often hilarious, Sergio has to say about his part of the business.

PG: I’ve been seeing Mercury transformers in amps for at least a decade. When did you get into the amp scene?

SH: This happens to be one of our most often asked questions. Even though Mercury Magnetics’ roots go all the way back to the early 1950s, there are guitar players who are only now discovering us. But if an industry insider like you has been aware of us for at least a decade, then I suppose it means I don’t need to lay off any of our sales and marketing staff.

I would attribute most of our lingering anonymity to the old days. Back then, most of our clients from the audio community preferred to keep us as a trade secret from their competitors and the press. The typical transformer-savvy amp builder also didn’t usually want to share the credit with us, or reveal what their “unique” technical advantage was regarding audio and tone. Consequently, we were asked to maintain a low profile and generic look for our transformers for quite some time. On occasion, a customer in the know will spot a small “MM” mark on a transformer from an older piece of gear, and ask if it’s a Mercury. Odds are that it is.

It was the guitar amp crowd that pushed us to go above ground. Now Mercury gives any electric guitar player or amp restorer a taste of what the pros were using, talking about in their studios, and among themselves. Many players have told us their amps increased in value when upgraded with Mercury transformers, and this became evident when insurance appraisers began to contact us for verification. However, it wasn’t until the mid-1980s when we began to market our services and various brands to guitar players.

For me personally, I got into the amp scene around the mid- to late 1970s. I just found it to be a nice way to relax from the strain of oversleeping.

PG: Your website shows a large number of amp manufacturers you have replacement/upgraded transformers for. What are your best sellers and why?

SH: There are so many different camps loyal to their particular amp brand, so it would be difficult to single out the best sellers. The best sellers are transitory and change from week to week because guitar amp players are a fickle bunch. That’s why we’ve built the world’s largest catalog of guitar amp transformers where nobody is left out.

But trends tend to follow their own dynamics. And the current worldwide trend seems toward smaller wattage amps—regardless of brand. Conversely, the 100-watt heads are not selling like they used to. Players are gigging with no more than 15 watts and a few pedals. Regardless of playing style, they’re doing just fine abiding by sound level restrictions and kicking ass with the tone we feel Mercury upgraded amps deliver.

These players really get the fact that an amp lacking in tone can’t be fixed with higher power or covered up with a gain mod. An amp that coughs out an asthmatic tone at 50 or 100 watts easily fatigues both music listeners and guitarists. But the audience will stay until the bar closes if the band plays well and sounds great—even with as little as a few watts going through the available PA system.

PG: What can a guitarist expect to hear when upgrading their transformers in a newer amp?

SH: An amp’s transformers are the most important component in determining the quality of amplified guitar tone. And it’s no coincidence that they’re the most expensive parts in an amplifier. Many of the newer amps just don’t have the same “overkill” factor with their transformers as the amps in the ’50s and ’60s. Why? Ignorance and a bean-counter mentality. What’s good for accounting isn’t necessarily good for tone from an amp. Sadly, the people making these decisions are probably not players themselves and don’t seem to realize the damage they’re doing to the industry.

It’s not unusual to find a current production amp with a power transformer running hotter than hell, even without cranking the amp all the way. Or having an undersized, cheaply built output transformer whose sphincter begins to tighten the moment the guitarist reaches for the amp’s volume knob. An amp built around anemic transformers yields only to dull, thin, noisy, fuzzy mids and mushy bass. That’s what makes your notes sound more like farts through a pillow. This overkill factor is probably the only edge that some of the vintage amps have over the newer amps.

We have made it our mission to duplicate the performance of the best original transformer designs of all time. In terms of amplified guitar tone history, these transformers represent the best ever produced.—Sergio Hamernik

Have you ever noticed how most newer amps often weigh less, sometimes a lot less, than the older ones? That’s usually the weight difference between the old and new transformer designs. There is a direct relationship between weight and having transformers that seem to stay cooler and “loaf around” with power to spare, until a player demands more from their amp. It’s like they are waiting around having a card game, waiting for the player to do something. The best vintage tone was born that way. Newer amp tone can be easily improved—if the builder follows some of the same ideas.

Upgrading with quality transformers gives a second chance to a new amp owner to make things right with their tone, by reclaiming that overkill factor. Assuming there are no issues with the amp’s circuitry like bad parts or worn out tubes, a guitarist should hear and feel improvements with the very first pluck of the guitar. They should expect to hear the notes more detailed with overtones, and a quicker and more immediate response to their playing. Clean notes will have less sonic collisions with noise and reveal more bell tones, chimes, etc.

When more distortion is required, the player will sense better control of crunch and when break-up begins to happen. The coughing and hacking that happens when a stock amp is pushed, will vanish with a transformer upgrade. It will be replaced with longer sustains and notes that reach farther. The amp will also sound closer and bigger than the power it puts out—and the bass notes will have a tighter, rounder bottom end. And when pushed, she will still be able to hold that quarter from dropping—no matter how tall her high heels—something most musicians are looking for.

It’s not uncommon for guitarists to report that it took a few weeks of playing to fully realize what they’ve gained in terms of harmonic richness. These players have typically played longer and felt more inspirational emotions sucking them in, as they have invested more time into relearning and becoming reacquainted with their amps.

PG: Many players become very attached to the transformers in their vintage amps. When you create ToneClones or Radiospares and Partridge versions of these classic transformers, how close are they get to the originals?

SH: Radiospares and Partridge are our brand specific clones, whereas ToneClones are “best-of-breed” duplicates culled from the hundreds of other brands that have made transformers over the years.

We have made it our mission to duplicate the performance of the best original transformer designs of all time. In terms of amplified guitar tone history, these transformers represent the best ever produced. In the grand scheme of tone pursuit, these designs are incredibility important and deserve to be considered treasures.

This is an ongoing project for us, spanning almost three decades now. And it couldn’t have been accomplished without the enormous amount of assistance we’ve received from top players and amp collectors around the world.

What about Axiom transformers? Where do they fit in?

The Axiom transformer line takes over where the limitations of vintage transformer design ended. No bean counters here—simply the sincere pursuit of answering the age-old question: What if there were no constraints on budget, time, or material quality to achieve the best possible performance? That’s our objective with the Axiom line.

Axiom transformer designs represent many new approaches—new tone with the best materials and designs money can buy, so they’re not intended for the timid or the low-budget crowd. Check out our FatStacks and SuperStacks for the Marshall DSL and TSL families for interesting comparisons.

PG: Mercury’s vintage transformer restoration service has been gaining a reputation for quality work. Why would someone want to restore a transformer instead of replacing it? And vise-versa?

SH: Some vintage amp owners prefer to pay the extra cost of our restoration services, because it’s very important to them that their amps retain authenticity. Collectables or rarities are valuable. They’re of the “why take chances” mind. The high road. But on the flip side, we have pro musicians who insist on touring with their vintage gear. To play it safe, and not sacrifice the tone of their original transformers, they have their techs replace the stock transformers with Mercury’s. By doing this, they preserve the original transformers from road abuse while taking advantage of our reputation for tone, durability, and warranty. Restoration of vintage transformers is a tricky and highly specialized art. Sadly, too many of the great originals have been lost forever due to technically inept and musically disinterested people. We see attempts at “rewinds” here all the time.

Occasionally, it appears some people confuse “demolition” with “restoration,” and the preservation of the original tone is lost forever. There’s no shortcut to doing a proper restoration.

PG: I understand you’re doing all of your labor and get all of your materials in the USA. How does that impact your business aside from just the straight costs?

SH: Well, we figured that someone has to do it—and we really do make everything here with 100 percent American materials. There are plenty of products out there stamped with “Made in the USA,” but are actually assembled with non-USA, low-price materials. But yeah, we’re the real deal and proud of it.

Building transformers that make an amp sound good requires highly specialized technologies, highly skilled labor, and the right kind of materials. We love music and owe it to the players out there to do all the work “in-house,” so we can keep tight control over every aspect of our transformer designs. It’s really old-school military spec style, so our transformers don’t vary at all from batch to batch. If you need a replacement transformer 10 years from now, it’ll sound exactly the same as the one it’s replacing.

We’re hard-liners when it comes to not playing shell games with a musician’s hard earned dough and quest for better tone. Perhaps I’m a fool for doing it this way, but I was brought up in a musically minded family. From a very early age, I was taught that music is as important and necessary as food. If there is a day our services are no longer needed or appreciated, I’ll pursue my dream of owning a car wash in the valley, and get into the business of making money.

PG: Any new or exciting projects in the works at Mercury?

SH: Yes, but we’re planning on releasing the news sometime around summer. For quite some time, we’ve been fielding requests for accessories to accompany our transformer line. We’re being asked to apply our know-how to other aspects of guitar amps.

PG: Do you have any advice for guitar players and techs in their quest for tone?

SH: Don’t let anybody fool you—every player has the ability to discern the difference between good or bad tone. Unfortunately, there are a few too many self-styled “experts” who irresponsibly dispense advice without having a clue. As a result, we’ve all seen amps completely lose their tone by being modded to death.

There’s no excuse for the old “damn, I’ve done it this way for many years so it must be right” mentality. More than ever, it’s so easy to seek opinion, advice, and help online and elsewhere. I highly recommend the old textbooks from the 1950s and 1960s as a good place to start on vacuum tube audio circuits.

Do your homework and follow what the smart players are doing—improving your tone isn’t that elusive. If what you have sounds good to you, leave it alone. But if you know your amp’s tone could use some improvement, then start where it begins… the transformers. PG

Weber output transformer

All and all not bad. The bottom is a bit boomy but it’s an easy fix. I did have to dial the bass down for the recording. The distortion seems loose and undefined. My dad likes the thickness, but he’s all about some Slow Hand’s “Woman tone.” If you’re on a budget definitely not a bad buy.

Heyboer output transformer

Clean is decent but this is probably my least favorite of the bunch. Way too muddy and grainy when distorted. I don’t like the feel of this transformer, and it has some weird mid-harmonics. It never seemed happy no matter how I set it.

Classic Tone output transformer

Clean is fantastic. Has great rich mids and terrific high-end sparkle but the bass is a bit thin. This transformer has a nice sweet spot but turning the knobs all the way up or down doesn’t have much effect on the sound. So it’s not as versatile as I would have liked. Still a little loose on the distortion but with good clarity. Definitely a great buy.

Hammond output transformer

Great Clean. The controls were very responsive but not what I’m going for with this amp. For whatever reason this pulls out all the Stevie Ray tones. My Tele always sounds like a Strat when using this transformer. It’s nice but not right for this rig. If I build a Fender in the future I might do another shoot out, and Hammond would definitely make the lineup.

Marstran Radiospares output transformer

I played this up a half step… whoops… and I blew fuse at the end of the recording and that’s why the demo is a little shorter than the others. The overall tone is harsh and I couldn’t get it smoothed out to save my life. The highs and mids are really sharp and spikey. The very top is shrill and thin. It also had some strange harmonics that just aren’t pleasant.

Mercury Magnetics Radiospares output transformer

This is by far the most versatile transformer out of the bunch. You can dial this thing any which way and it sounds great. The bass is full but not boomy. The mids are rich and smooth. The highs sing and sparkle but aren’t thin. The harmonics are ideal and even across the board. The distortion is the tightest and no matter how hard the amp is driven each note still has clarity. The touch sensitivity is unreal. With the amp almost dimmed you can play soft and hardly hear any distortion. Then you can bang out a chord or dig into some lead and the amp will scream. Yeah, it may cost four times as much, but as the old saying goes, “You get what you pay for.”

Source: https://mercurymagnetics.com/pages/news/misc/ShootOut.htm

Zitat über Mercury Magnetics bei Boutique Verstärker Seite 139

Diese Transformatoren gehören zu den besten Ausgangsübertragern, die auf dem Markt heute erhältlich sind. Sie werden sehr aufwendig und mit den besten Materialien hergestellt, um so nah wie möglich an die wunderbaren alten Transformatoren der Firma Radiospares aus den 60er Jahre heranzukommen. Der Stahl wird noch von Hand geglüht, im Gegensatz zu modernen Transformatoren, welche eine Silizium-Stahl-Legierung verwenden. Die Sound-Unterschiede sind gravierend.

English translation: “These transformers are known as the best output transformers available on the market today. Their production is very complex and just the best materials are used to reach as close as possible the wonderful old transformers from the company ‘Radiospares’ from the sixties. The steel is still annealed by hand – compared to the modern transformers which use a silicium steel alloy. The sound differences are enormous.”

If you want to nail Clapton’s tone, a crucial part of the equation is the amplifier. With a little ingenuity, John Wiley shows you how to turn your reissue Bluesbreaker combo into the real deal.

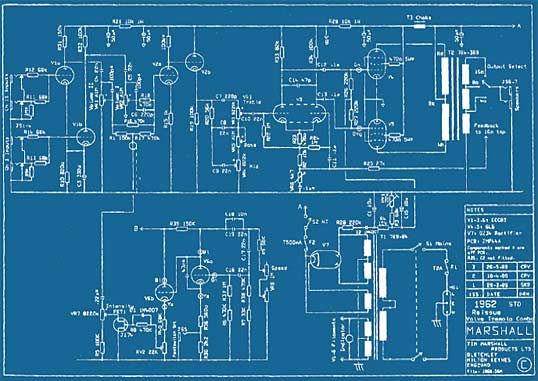

A unique distinction of early Marshall amplifiers is that none of them within the same model line sound exactly alike. Partly attributable to founder Jim Marshall’s penchant for working with budding British musicians and working many of their suggestions into his designs, and partly due to the difficulties of locating reliable parts suppliers, Marshall’s early designs each had their own personality. For instance, Marshall’s Model 1962 combo was, itself, an ordinary amplifier; however, one particular Model 1962 used by Eric Clapton with John Mayall and the Bluesbreakers had such a revolutionary tone that it created a new sound in the still-young world of rock n’ roll.

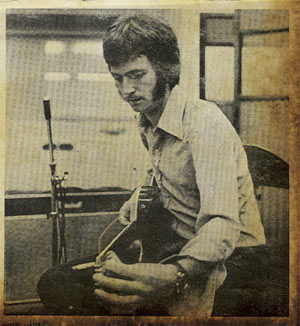

In 1965, Clapton found himself the featured guitarist in John Mayall and the Bluesbreakers. Armed with a 1960 Gibson Les Paul and the Marshall Model 1962 combo amplifier, he single-handedly discovered a combination of guitar and amp that produced an extraordinary howl — Clapton achieved his trademark sound by playing the amplifier at full volume. The sound was full-bodied, authoritative, but not overly distorted; it easily cut through the other band instruments. The sustain was pure, the treble notes sang and the bass registers exhibited a “throaty” bottom. At such high volumes, the amp was prone to feeding back, and this provided an awesome effect to the overall sound.

This image, from the Beano LP, shows Clapton tuning up, with his Model 1962 in the background.

The blistering tone was captured on vinyl and released to an unwitting public as John Mayall and the Bluesbreakers with Eric Clapton; also known as the “Beano” album, it quickly shot to number six on the British charts, even amongst the din of other popular British and American pop groups such as the Beatles, the Animals, the Rolling Stones and the Beach Boys. That LP’s impact soon spread to America and abroad, inspiring legions of new guitarists around the world — especially influencing musical rebels in the United States. Clapton’s playing style, combined with a ferocious amplified tone, seemed to inject a new and exciting dimension into the young blues-rock genre. But none of this could have happened without the small British amp company, Vox. Models like the AC30 would provide the “British Invasion” with its unique sound, and convinced Marshall to build a compact amplifier for his new company; the initial development of Marshall’s first combo took place in early 1964. In a 2003 interview with Musician’s Hotline magazine, he claimed the Model 1962 was built at the request of Eric Clapton. “Eric used to practice in my shop and he was one of the first guitarists to ask me to build a combo,” Marshall recalled. “He wanted one so it would be easy for him to put the whole thing in the boot [trunk] of his car.”

Unfortunately, that Model 1962 disappeared, with Clapton himself unsure of what became of it; years later, it would become known as the holy grail of combos. Although those early combos had great tone, no two sound exactly the same. Two decades later, the Marshall reissue would sound nothing like it at all.

The Reissue

For many of us, the year 1990 brought an answer to one of our greatest wishes: the Marshall Model 1962 2×12 combo was finally reissued. The idea had apparently been in the works for quite some time, as evidenced by this author’s correspondence to a Marshall factory director, Keith Carnall in the late months of 1984. Carnall’s reply stated, “We have thought many times about running a ‘vintage special,’ with valve rectification and all the other old goodies… let us just say for now that it is an idea that we will continue to work around and perhaps you will get your wish granted.” Although Clapton was not aware of the amp being reissued, Marshall christened it the “Bluesbreaker,” in his honor. When asked in a 1989 Guitar World interview he replied, “Did they really? How sweet. I didn’t even know that. How does it sound?” Marshall simultaneously introduced the Bluesbreaker and the JTM45 in 1990, along with the new JCM900 series.